A-A-55601B

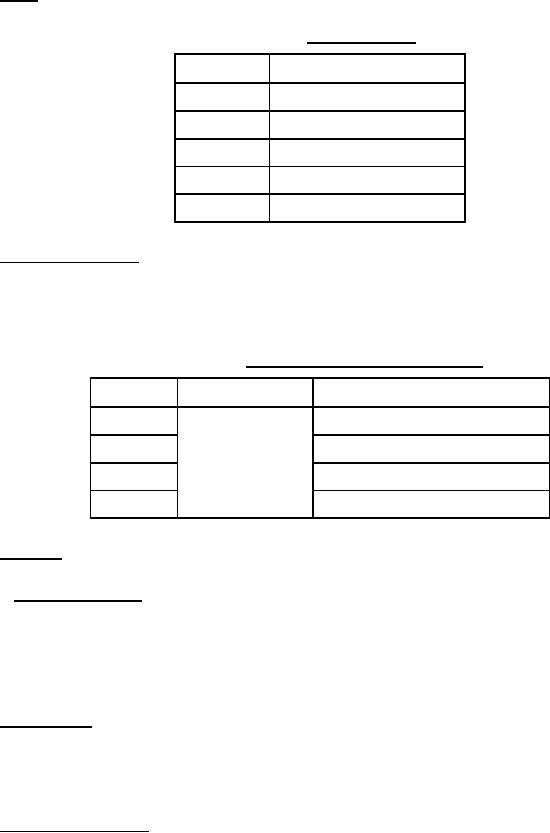

3.2 Cage. The cage shall be one of the coded options in table II (see 7.3(c)).

TABLE II. Cage materials.

Cage code

Material type

A

Manufacturer's standard

B

Brass

M

Machined brass

N

Non-metallic

J

Steel

3.3 Precision tolerance. The bearing precision tolerance level shall be RBEC-1 as defined in

ABMA 20, "Radial Bearings of Ball, Cylindrical Roller and Spherical Roller Types, Metric

Design". The associated radial internal clearance shall be one of the coded options listed in

table III (see 7.3(d)).

TABLE III. Precision tolerance requirements.

Code

Tolerance class

Radial internal clearance

C2

Group 2 (less than normal)

C0

Group N (normal)

RBEC-1

C3

Group 3 (greater than normal)

C4

Group 4 (greater than 3)

3.4 Material.

3.4.1 Rings and rollers. Rings and rollers shall be made of chromium-alloy steel 52100

(UNS G52986) conforming to SAE-AMS 6440, "Steel, Bars, Forgings, and Tubing 1.45Cr

(0.93 - 1.05C) (SAE 52100) For Bearing Applications". The hardness of rings and rollers shall

be 58 to 66 RC in accordance with ASTM E 18, "Standard Test Methods for Rockwell Hardness

and Rockwell Superficial Hardness of Metallic Materials".

3.5 Load ratings. Basic load ratings shall be calculated using the method specified in ABMA 11,

"Load Ratings and Fatigue Life for Roller Bearings".

4. REGULATORY REQUIREMENTS

4.1 Recovered materials. The offeror/contractor is encouraged to use recovered materials to the

maximum extent practicable, in accordance with paragraph 23.403 of the Federal Acquisition

Regulation (FAR).

4

For Parts Inquires submit RFQ to Parts Hangar, Inc.

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business